Expanded polystyrene

Undoubtedly the best-performing material on the market

Easy to use and highly economical, the EUROMAC2 formwork block is without doubt the most efficient on the market! It consists of two expanded polystyrene panels with a patented metal reinforcement molded into the walls. These spacers ensure the solidity of the walls and prevent any disassociation of the insulating panels over time.

The EUROMAC2 insulating formwork block is a high-performance material that eliminates thermal bridges, guarantees the best possible airtightness and effectively prevents any risk of condensation. It offers excellent thermal inertia to guarantee a constant temperature throughout the day, whatever the season.

Last but not least, the EUROMAC2 formwork block provides excellent acoustic insulation against external noise. The insulating concrete block facilitates the construction of your passive house walls, enabling 4 complex operations to be carried out in a single operation: wall assembly, installation of external insulation, waterproofing and acoustic insulation.

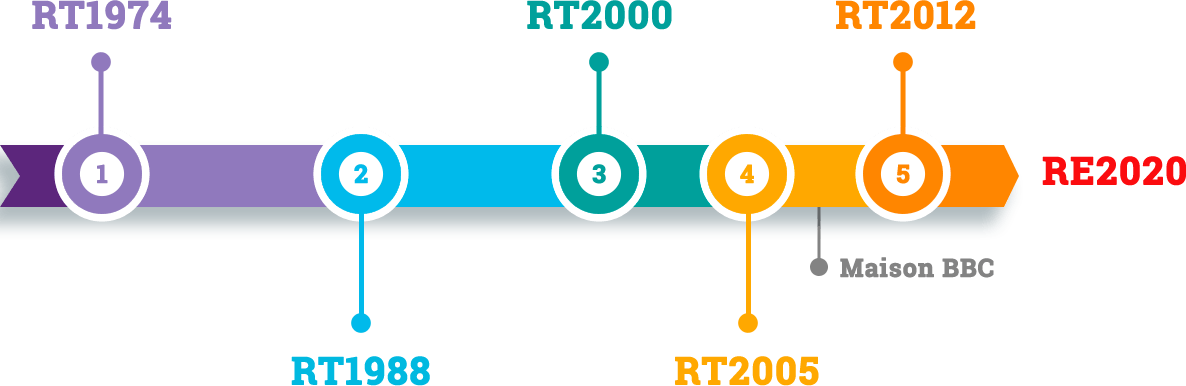

The EUROMAC2 insulating formwork block is at ease with all types of architecture, construction and finishing, and complies with RE 2020!

What is expanded polystyrene?

Expanded polystyrene (EPS) is a material obtained from the products of petroleum refining. At first glance, that's a far cry from ecological values!

However, EPS makes it possible to use styrene molecules, elements that have not been exploited by the oil industry. The styrene is then expanded and heated with steam to obtain small polystyrene beads that can reach up to 50 times their initial volume. These beads are finally compressed to produce sheets composed of just 2% material and 98% air! Production waste, less than 1%, is recycled and reused in the next cycle. This industrial process requires only steam and heat.

The advantages of expanded polystyrene

Each insulating formwork block consists of 2 polystyrene walls held together by thin metal spacers, inside which concrete is poured at floor level.

It's so easy to install, it's a hit with builders everywhere!

It's a lightweight material that's easy to handle and quick to assemble, since the formwork blocks fit together like bricks in a building set and require no fastening system (no glue or mortar).

EPS, a healthy material with no health risks

Composed of 98% air, expanded polystyrene (EPS) is inert, biologically neutral, stable over time and rot-proof. It contains no fibers and generates no particles. It does not support bacterial growth or trigger allergies. It is a non-irritant, non-toxic material used en masse in many fields, including microbiology, food packaging and, of course, construction. Expanded polystyrene (EPS) guarantees excellent indoor air quality in your home.

Good insulation saves natural resources

Expanded polystyrene (EPS) guarantees perfect insulation and excellent thermal performance! In the building sector, its use enables significant energy savings, reducing heating consumption by up to 90% compared with an uninsulated house. Less heating means fewer raw materials lost to combustion.

EPS, a healthy material with no health risks

Composed of 98% air, expanded polystyrene (EPS) is inert, biologically neutral, stable over time and rot-proof. It contains no fibers and generates no particles. It does not support bacterial growth or trigger allergies. It is a non-irritant, non-toxic material used en masse in many fields, including microbiology, food packaging and, of course, construction. Expanded polystyrene (EPS) guarantees excellent indoor air quality in your home.

Good insulation saves natural resources

Expanded polystyrene (EPS) guarantees perfect insulation and excellent thermal performance! In the building sector, its use enables significant energy savings, reducing heating consumption by up to 90% compared with an uninsulated house. Less heating means fewer raw materials lost to combustion.

Expanded polystyrene (EPS), a material ready for RE2020

The RT2012 thermal regulation requires that the energy consumption of new homes be limited to 50 kWh/m²/year. This standard is a first step towards the construction of passive or positive-energy houses, labelled BEPOS. The RE2020 environmental regulation sets the maximum limit for primary energy consumption at 15 kWh/m²/year. Expanded polystyrene (EPS) already meets this limit. It goes even further, enabling the construction of passive houses that use no main heating system at all! Certain types of insulation made with expanded polystyrene (EPS) meet Passive House targets and require no external energy input - they're self-sufficient and non-polluting!

About grey energy

Grey energy defines the energy expenditure required to produce a material over its entire life cycle. This unit takes into account the extraction of raw materials, the transformation phase, transport and the energy cost of recycling. Grey energy is evaluated in kWh/m3. Expanded polystyrene (EPS) represents an embodied energy of 0.3 to 0.85 MWh/m3. What's more, EPS provides the perfect exterior insulation for your home - and that changes everything!

A passive house built with EUROMAC2 insulation materials can do without gas and fuel oil! Expanded polystyrene (EPS) is the ideal material for building a passive or positive house! Further down the ranking, solid brick, still widely used in traditional construction, has an estimated grey energy of 1.2 MWh/m3!